ERP Systems: The ₹50 Lakh Mistake Most Factories Make

A mid-sized factory in Rajkot paid ₹55 lakhs for an ERP system. Eighteen months later, they were still using Excel spreadsheets.

The ERP worked—technically. It had all the modules: inventory, production planning, accounting, HR, CRM. The implementation consultants even got it running. Then they left.

Three weeks after go-live, the purchasing manager called the owner at 11 PM. "Sir, the system is asking for a 'purchase requisition approval workflow' but I need to order raw materials first thing tomorrow. What do I do?"

The owner didn't know. Neither did the production head. Or the accounts manager. The consultants had set up the workflows, but no one actually understood how to use them without hand-holding.

Within six weeks, employees found workarounds. They'd enter data into the ERP to keep management happy, but actual decisions were still made using the old Excel sheets. The ₹55 lakh system became very expensive compliance theater.

Sound familiar? 71% of Indian manufacturing companies report their ERP implementation either failed completely or didn't deliver expected benefits (NASSCOM Manufacturing Survey, 2023).

Why ERPs Fail: It's Not the Software

Mistake #1: Buying the System Before Fixing the Process

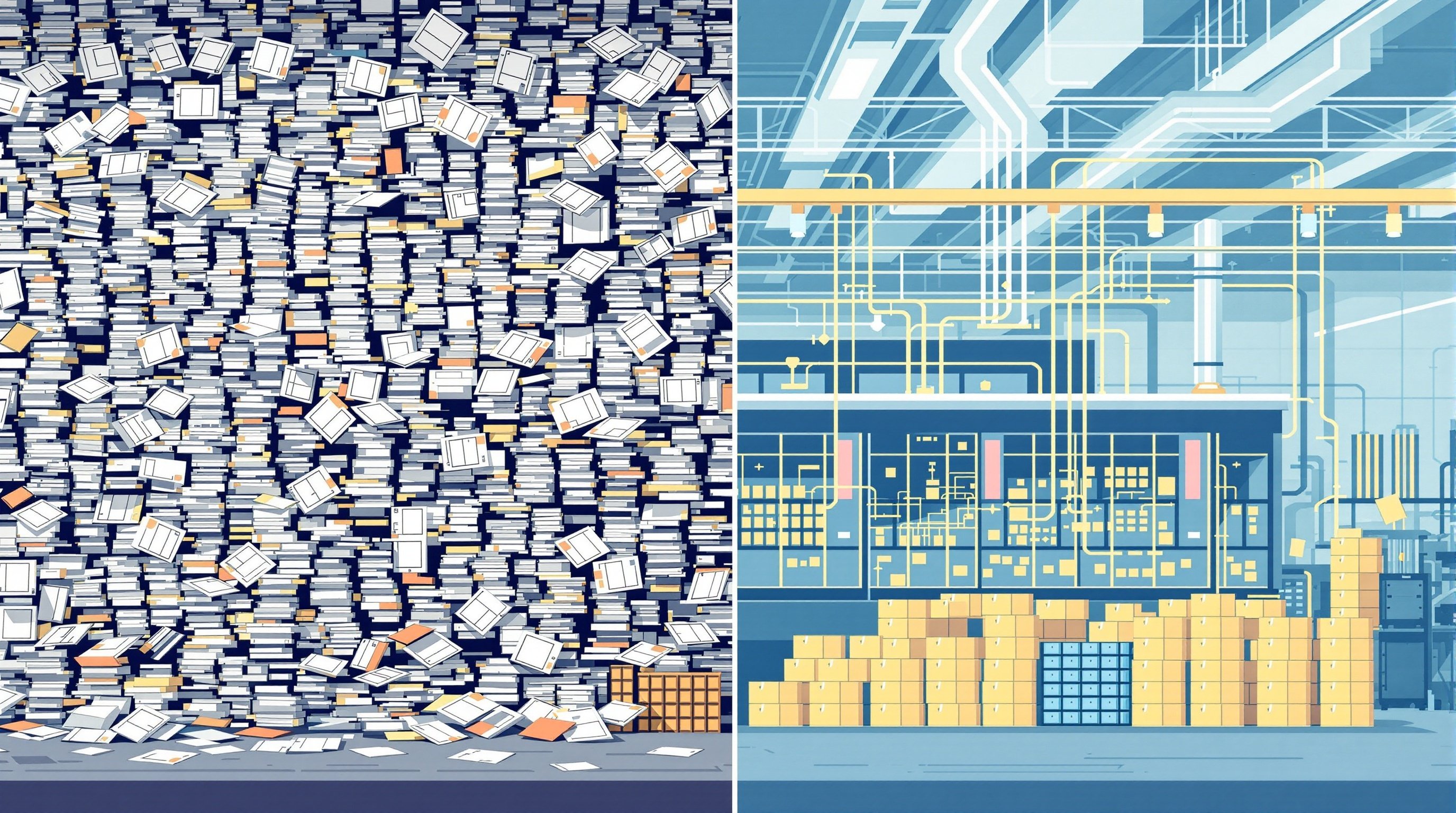

Your inventory management is chaotic. Items disappear. Stock counts are always wrong. Someone suggests, "We need an ERP!"

So you buy one. And now your chaotic process is digitized. Congratulations—you've automated chaos.

An electronics manufacturer in Noida implemented SAP. Months later, their inventory accuracy went from 76% to... 78%. They spent ₹1.2 crore to improve accuracy by 2%.

Why? Because the root problem wasn't lack of software. It was lack of process discipline. Workers didn't scan items when they took them from storage. The ERP couldn't fix that—only training and accountability could.

The fix: Before you even demo an ERP, document your current processes. Map them out. Identify what's broken. Fix it manually first. Then digitize.

Mistake #2: Treating Implementation as an IT Project

Here's how most ERP implementations go:

Management decides they need an ERP. They call the IT head. IT head evaluates vendors. Vendors demo their software. Management picks one. IT implements it.

Notice who's missing? The people who'll actually use it.

The production manager who needs to log daily output. The purchase officer who'll create POs. The warehouse supervisor who'll update inventory. None of them were in the room when decisions were made.

Result: The system is configured for an idealized workflow that looks great on paper but collapses when it meets reality on the shop floor.

The fix: Make implementation a business project, not an IT project. Your IT head should support it, but your COO or operations head should lead it. And involve end-users from day one.

Mistake #3: Underestimating the Training Investment

A factory owner in Ludhiana told me, "We spent ₹48 lakhs on the ERP. The vendor wanted another ₹12 lakhs for training. That's too much. We'll train internally."

Six months later, adoption rate: 31%.

Here's the math that hurts: If 70% of your team doesn't use the system properly, you're not getting 70% of the value. You're getting maybe 15% because the system only works when everyone uses it consistently.

You didn't save ₹12 lakhs on training. You wasted ₹40 lakhs on an underutilized system.

The fix: Budget 20-30% of software cost for training. Not one-time training—ongoing support for at least six months. And train in shifts, on the actual shop floor, with real scenarios.

What Actually Works: The Right-Sized ERP Approach

Let's talk about what successful ERP implementations look like.

1. Start with Phase 1, Not "Everything At Once"

Don't try to implement all modules simultaneously. A rubber manufacturing unit in Kerala got this right:

- Phase 1 (Months 1-3): Inventory management only. Get everyone comfortable.

- Phase 2 (Months 4-6): Add production planning.

- Phase 3 (Months 7-9): Integrate accounting.

- Phase 4 (Months 10-12): Add CRM and advanced features.

Total cost: ₹38 lakhs. Adoption rate after 12 months: 94%. ROI achievement: 16 months.

2. Choose Based on Complexity, Not Brand Name

SAP is great. For Tata Motors. Are you Tata Motors?

A 150-employee factory doesn't need enterprise-grade software designed for 15,000-employee corporations. You need something that:

- Handles your actual transaction volume

- Has local language support

- Offers phone support, not just email tickets

- Costs proportionally to your operation size

Sometimes the ₹12 lakh Indian solution works better than the ₹55 lakh German one.

3. The 80/20 Configuration Rule

Your ERP can do 1,000 things. You need 80 of them.

Configure only what you'll use in the next 6 months. Not what you might use someday. Not what's "best practice." What you'll actually use next week.

A automotive parts manufacturer configured just 15% of their ERP's capabilities initially. Six months later, they added more. A year later, more still. Current utilization: 62%—and that's considered excellent.

Compare that to factories that configure everything upfront. Average utilization: 23%. You're paying for 100%, using 23%.

4. Measure What Matters

Don't measure ERP success by "system uptime" or "data accuracy." Measure it by business outcomes:

- Did inventory carrying costs decrease?

- Did order fulfillment time improve?

- Did you reduce emergency purchases?

- Are you making decisions faster?

If the answer is no, the ERP isn't working—regardless of what the IT metrics say.

The Real Checklist Before You Buy

Before signing that ERP contract, honestly answer these:

- Have we documented and optimized our current processes?

- Does the implementation budget include 6+ months of training?

- Are we implementing in phases or trying to do everything at once?

- Will our actual end-users lead the implementation, not just IT?

- Does the vendor have local support we can call at 9 PM?

- Are we measuring business outcomes, not just technical metrics?

If you can't confidently say yes to all six, delay the purchase. Work on your processes first. The right time to buy an ERP is when you've outgrown your current system—not when you're trying to fix a broken one.

That ₹50 lakh mistake? It's entirely avoidable. But only if you do the boring work first: process mapping, user involvement, phased rollout, extensive training.

The factories that succeed with ERP aren't the ones with the most expensive systems. They're the ones that did their homework.

If this helped you see through the noise, share it with another factory owner, COO, or plant head wrestling with the same questions. Forward it on WhatsApp, post it on LinkedIn or X, or print it out for your Monday morning production meeting.

And if they haven't subscribed yet? Point them to thefactoryai.in. Two emails a week, zero fluff.