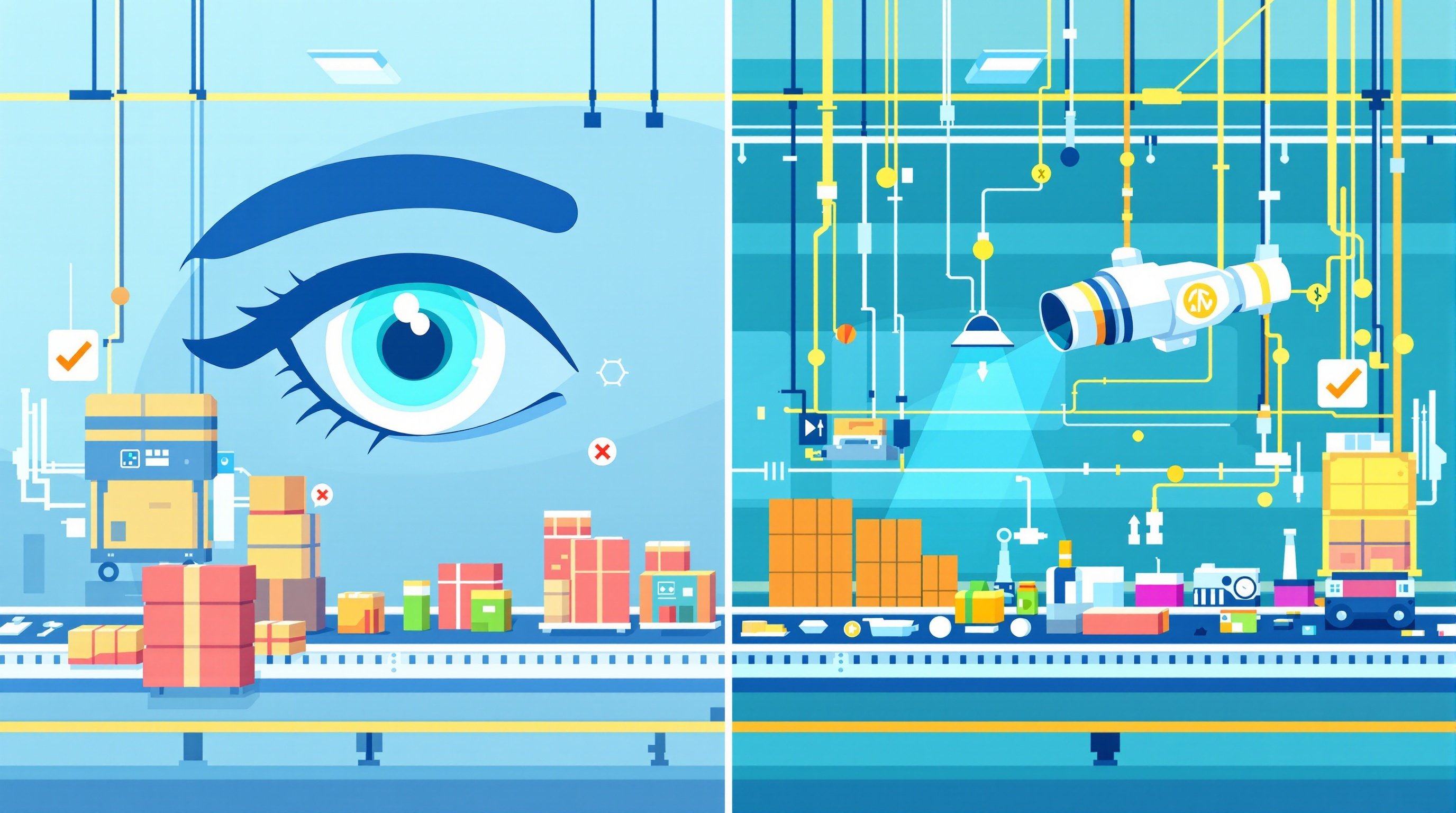

Quality Control 2.0: When Machines See Better Than Humans

The QC inspector had been checking PCB boards for 12 years. He was good—caught about 94% of defects. Management considered that excellent.

Then they installed a computer vision system. It caught 99.2% of defects. Plus defects the inspector didn't even know to look for.

The inspector wasn't happy initially. "A camera can't replace experience," he insisted.

He was right—and wrong. The camera couldn't replace his judgment. But it could see things his eyes physically couldn't. Microcracks measuring 0.02mm. Color variations of 0.3% RGB difference. Inconsistencies he'd never consciously notice because they were below human perception threshold.

Six months later, the same inspector: "I should have trusted the data sooner."

The Human Vision Limitation

Let's be honest about what humans are great at—and what we're not.

Humans excel at:

- Complex judgment calls with ambiguous criteria

- Adapting to new defect types instantly

- Understanding context and intent

- Handling unpredictable variations

Humans struggle with:

- Consistency over 8-hour shifts

- Detecting subtle variations

- Speed—we can only inspect so fast

- Objective measurement—"acceptable" is subjective

A ceramic tile factory studied their human QC team. Morning shift (8 AM - 12 PM): 97% accuracy. Post-lunch (1 PM - 3 PM): 94% accuracy. Last two hours (3 PM - 5 PM): 89% accuracy.

It's not that inspectors got lazy. They got tired. Human eyes fatigue. Computer vision doesn't.

When Computer Vision Actually Works

Use Case #1: High-Speed Inspection

A pharmaceutical packaging line runs at 180 bottles per minute. That's 3 per second. Human inspectors could check maybe 1 per second, carefully.

They had 6 QC stations, each inspector checking a sample: every 3rd bottle. So 67% of production was uninspected.

Computer vision system: 4 cameras, 180 bottles per minute, 100% inspection. Cost: ₹22 lakhs. Defects caught that previously reached customers: Reduced 94%.

Customer complaints dropped so dramatically, the company recovered the ₹22 lakh investment in 14 months purely from reduced returns and rework.

Use Case #2: Microscopic Defects

An electronics manufacturer made connectors. Critical defect: Pins misaligned by 0.05mm or more would cause connection failures.

Human inspectors with magnifying glasses caught about 80% of these. The other 20%? Warranty claims. Lots of them.

Computer vision with high-resolution cameras (8 megapixels) and sub-pixel measurement algorithms: 99.7% catch rate.

Warranty claims dropped 88%. That alone saved ₹38 lakhs annually. System cost: ₹18 lakhs. ROI: 5.7 months.

Use Case #3: Multi-Feature Inspection

An auto component factory checked 12 different features per part: dimensions, surface finish, color, logo placement, hole diameter, thread quality, etc.

Human inspectors took 45 seconds per part. Production output: 800 parts per shift. They needed 10 inspectors to keep up.

Computer vision system checked all 12 features simultaneously in 0.8 seconds. One system replaced 10 inspectors.

Before you think "They fired 10 people"—they didn't. They moved them to final assembly where human judgment and dexterity were actually needed. Output increased 30% because assembly was no longer the bottleneck.

The Real Cost-Benefit Math

Let's break down typical costs for a mid-sized implementation:

System Cost:

- Industrial cameras (2-4 units): ₹6-12 lakhs

- Lighting system (critical for quality images): ₹2-4 lakhs

- Vision software and ML training: ₹8-15 lakhs

- Integration and setup: ₹4-6 lakhs

- Total: ₹20-37 lakhs

Ongoing Costs:

- Software licensing: ₹1-2 lakhs/year

- Maintenance: ₹1 lakh/year

- Retraining for new products: ₹1-2 lakhs per new product line

Savings (Typical):

- Reduced defect escapes: ₹15-40 lakhs/year (warranty, returns, reputation)

- Reduced rework: ₹8-15 lakhs/year

- Increased inspection speed: Often 3-5x faster—either more throughput or fewer inspectors

- Consistent quality: No shift-to-shift variation

Typical payback: 12-24 months.

When NOT to Use Computer Vision

It's not always the answer. Here's when to skip it:

1. Low Volume, High Mix Production

If you make 50 different products, 10 units each per month, training vision systems for each variant is expensive and time-consuming.

A custom job shop tried this. Training time per new product: 8 hours. They made 30 different parts monthly. That's 240 hours of training work. Humans remained more flexible.

2. Highly Subjective Quality Criteria

"Good finish" for leather goods, wooden furniture, or hand-crafted items—these involve aesthetic judgment that's hard to codify.

You can teach a computer "scratch longer than 5mm," but teaching it "this finish looks premium" is much harder.

3. When Defect Cost is Lower Than System Cost

A factory making ₹20 components considered a ₹25 lakh vision system. Their annual defect-related costs: ₹4 lakhs.

Even if the system eliminated 100% of defects, payback would be 6+ years. By then, the system would likely need replacement. They stuck with human inspection.

The Implementation Reality

Most factories assume computer vision is plug-and-play. It's not.

The Training Phase

You need 500-2,000 images of good parts and 200-500 images of each defect type to train the system properly.

A fastener manufacturer thought they could go live in 2 weeks. Reality: 6 weeks. Why?

- Week 1-2: Captured baseline images

- Week 3: Realized lighting was inconsistent—retook images

- Week 4: Initial training—accuracy only 91%

- Week 5: Added more defect examples, retrained—accuracy 97%

- Week 6: Fine-tuning and validation

Plan for 4-8 weeks from installation to full production use.

The Hybrid Approach Works Best

A metal stamping factory got it right. Their vision system inspects 100% of parts at high speed, flagging any defects.

But flagged parts go to a human inspector for final call. Why?

Because the vision system has a 2% false positive rate. At 5,000 parts per day, that's 100 false positives. Having humans quickly verify these 100 is faster than manually inspecting all 5,000.

Result: Computer speed, human judgment, best of both.

Practical Implementation Steps

If you're considering computer vision QC:

Step 1: Identify the Right Application

- High volume production?

- Objective, measurable defects?

- Speed or microscopic precision needed?

If yes to 2 of 3, it's worth exploring.

Step 2: Pilot on One Product Line

Don't try to inspect everything. Pick your highest-volume or highest-cost-of-defect product. Prove the concept there.

Step 3: Get Lighting Right (Critical!)

70% of computer vision failures are due to poor lighting. Invest in proper industrial LED lighting. Consistent, shadow-free, controlled.

Step 4: Budget Training Time

Capture images across normal variation—different material lots, different times of day, different operators. The more variation in training data, the more robust the system.

Step 5: Measure Real-World Accuracy

Demo accuracy means nothing. What matters is accuracy on your production line, in your environment, with your parts.

Run a parallel trial: Vision system + human inspector both checking for 2 weeks. Compare results. That's your real accuracy.

The Bottom Line

Computer vision isn't about replacing human inspectors entirely. It's about doing what humans can't: seeing microscopic details, maintaining consistency for 24 hours, inspecting at inhuman speeds.

Where it works—high volume, objective defects, need for speed—it's transformative. 12-24 month payback with massive quality improvements.

Where it doesn't—low volume, subjective criteria, inexpensive components—stick with humans.

And often, the best answer is hybrid: machines for speed and consistency, humans for judgment and validation.

That PCB inspector who was skeptical? He's now the vision system supervisor. He trains the AI, validates edge cases, and handles complex scenarios the computer isn't sure about.

He's not less valuable. He's more valuable—because now he's augmented by technology that sees what he can't.

If this helped you see through the noise, share it with another factory owner, COO, or plant head wrestling with the same questions. Forward it on WhatsApp, post it on LinkedIn or X, or print it out for your Monday morning production meeting.

And if they haven't subscribed yet? Point them to thefactoryai.in. Two emails a week, zero fluff.